← Return to Home

Measuring: Calipers, Scales & Micrometers

Learned precision measurement techniques using dial calipers, digital scales, and micrometers. Measured various metal components to within a tolerance of ±0.003 inches. Developed accuracy and attention to detail essential for machining and quality control in manufacturing.

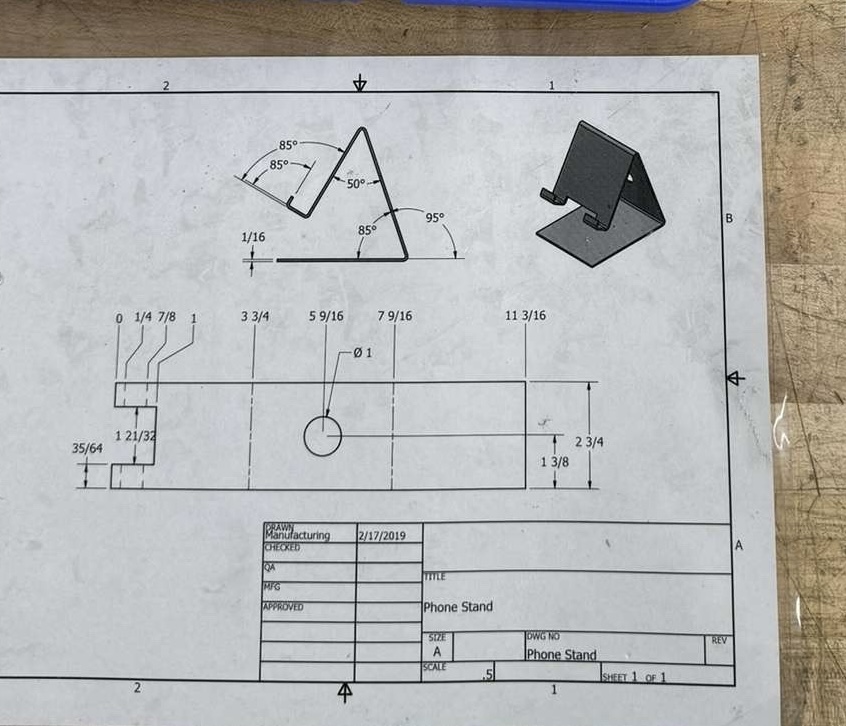

Sheet & Plate Forming: Phone Stand

Fabricated a phone stand using a press brake to bend sheet metal to specified angles. Applied layout techniques to mark bend lines and executed multiple brake operations. Gained hands-on experience with sheet metal forming, bend allowances, and safe handling of forming equipment.

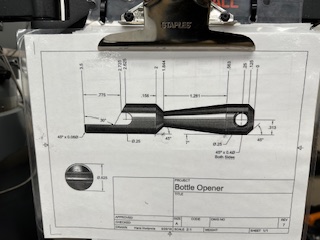

Manual Mill & Lathe: Bottle Opener

Machined a bottle opener from aluminum stock using both a manual mill and lathe. Performed facing, drilling, and slotting operations while maintaining dimensional accuracy. Gained experience in tool setup, feeds and speeds, and traditional machining techniques.

CNC G-Code: Bottle Opener

Programmed and machined a bottle opener using CNC equipment with custom-written G-code. Reduced machining time to under 2 minutes. Learned CNC workflow including part setup, tool path generation, and post-processing. Strengthened understanding of automation and rapid manufacturing.

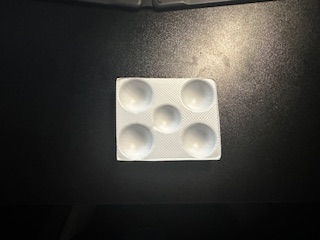

Vacuum Forming & Pressing: Paint Tray

Designed and produced a paint tray using vacuum forming. Created a mold, heated plastic sheets, and applied vacuum pressure to form the final part. Learned mold preparation, plastic behavior under heat, and mass-production forming techniques.

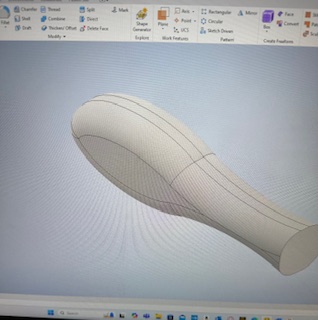

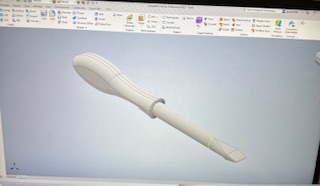

Injection Molding: Flathead & Phillips Screwdrivers

Created both flathead and Phillips screwdrivers using the injection molding process. Modeled handle designs in CAD and used metal inserts for screwdriver tips. Focused on mold fit, part symmetry, and surface finish. Practiced assembly and dimensional checks post-molding.

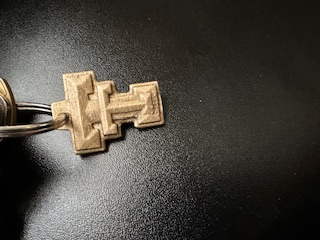

Sand Casting: Texas Tech Logo

Produced an aluminum casting of the Texas Tech logo using sand casting techniques. Prepared molds by packing sand tightly around the pattern, removed the pattern, and poured molten aluminum. Finished the part using grinding tools for smooth edges and clean visuals.

Forging: Steel Hook

Forged a steel hook using a hammer and anvil after heating the metal in a furnace. Practiced shaping techniques, material control, and quenching. Developed an understanding of deformation processes and how temperature affects metalworking.

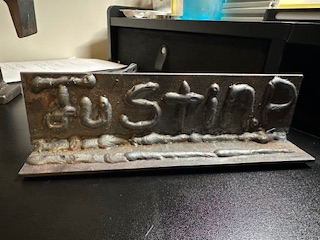

Welding: Nameplate & Double-T Beam

Fabricated a custom nameplate and Texas Tech “Double T” beam using MIG welding. Cut metal sections, tacked components into position, and performed weld passes. Learned joint preparation, weld bead control, and post-weld cleanup for professional results.